Posted by Stephen head on 14th Sep 2025

Building the Manito Cajon: Journey, Wood, and Respect Between Builders

Looking Up to Manito Percussion

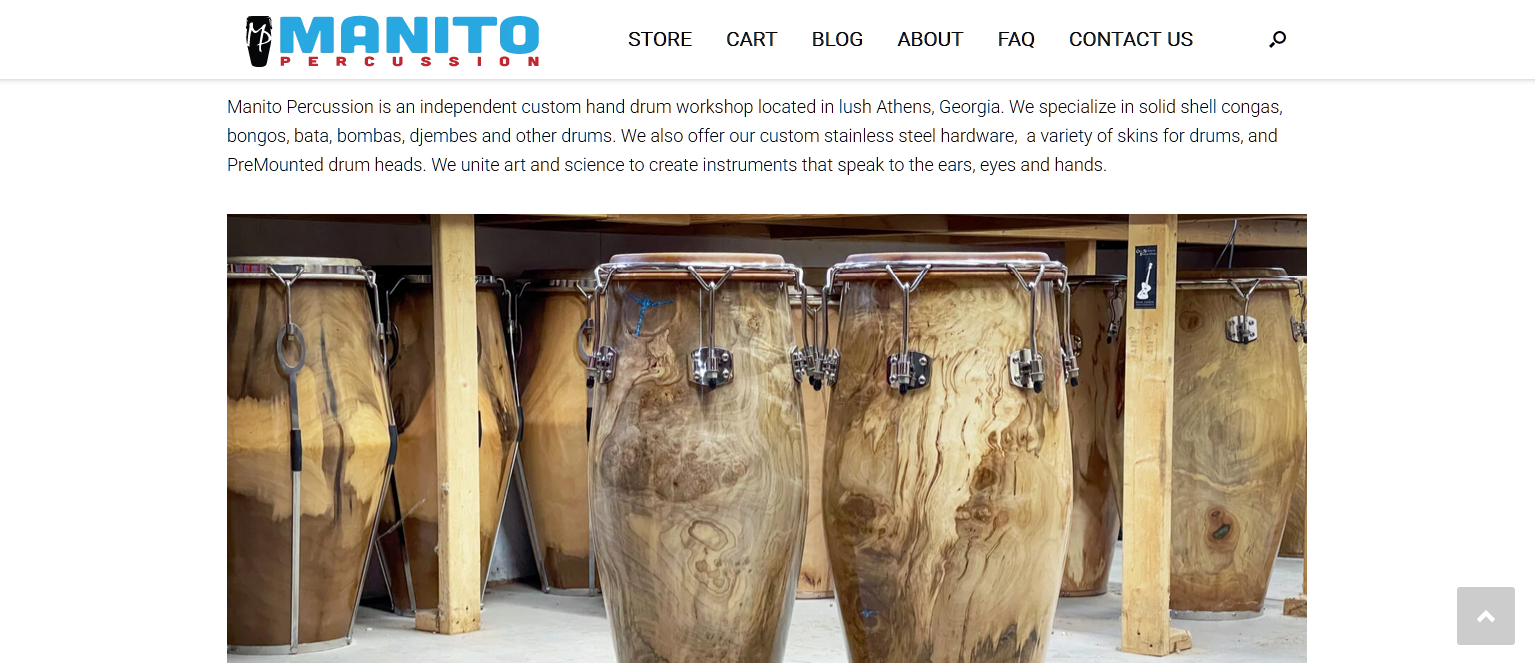

I’ve been building cajons for nearly 17 years. Over that time, I’ve studied other builders, pushed myself to refine my technique, and handcrafted more drums than I can count. Each build has taught me something....sometimes small, sometimes life-changing....and I’ve carried those lessons into every project that comes after. About ten years ago I discovered the work of Ryan Wendell of Manito Percussion. If you are not familiar with his work, you need to check it out. He turns congas out of solid tree trunks! I started following his work closely. Over the years, I watched every video he released, studied his craftsmanship, and found myself inspired by the way he poured himself into his instruments. Ryan became, in many ways, one of the builders I measured myself against....not in competition, but in admiration. He is someone I look up to and someone I quietly have told myself, “That’s the kind of craftsman I want to become.”

A Conversation About Spalting

Not long ago, our paths crossed in a more personal way. I can’t remember if I first commented on one of his videos or he on one of mine, but eventually it led to us talking on the phone. What started as a quick chat turned into a long, detailed conversation about craft. One part of that conversation has always stayed with me. I told him I had noticed how often he worked with spalted woods. He explained the spalting process in depth—how different inoculations can create different colors and patterns in the wood. It was fascinating, and more than that, it reminded me of something important: this craft is not just about wood and glue. It’s about sharing knowledge, respecting each other’s paths, and passing along the lessons we’ve picked up along the way. That conversation became one of those anchor points for me, the kind you come back to later without realizing how significant it will be.

The Birthday Commission

Several months after that conversation, I received a message from Ryan’s wife, Annie. She told me how Ryan respects my work and that, for his 50th birthday, he wanted one of my cajons as his gift. I had to read it twice. Honestly, I was humbled in a way that’s hard to put into words. I told my wife about it right away. “This is a guy I’ve been looking up to for years,” I said. “This is the kind of builder I’ve admired and studied. And now he wants one of my drums.” There are certain milestones in a career that make you stop and take a breath. That was one of them for me. The only specifics Annie gave me were that Ryan wanted a bass port and an upholstered seat. Beyond that, he trusted me completely to choose the woods and design the instrument in the way I thought best. That kind of trust only added to the weight and meaning of this project.

Choosing the Woods

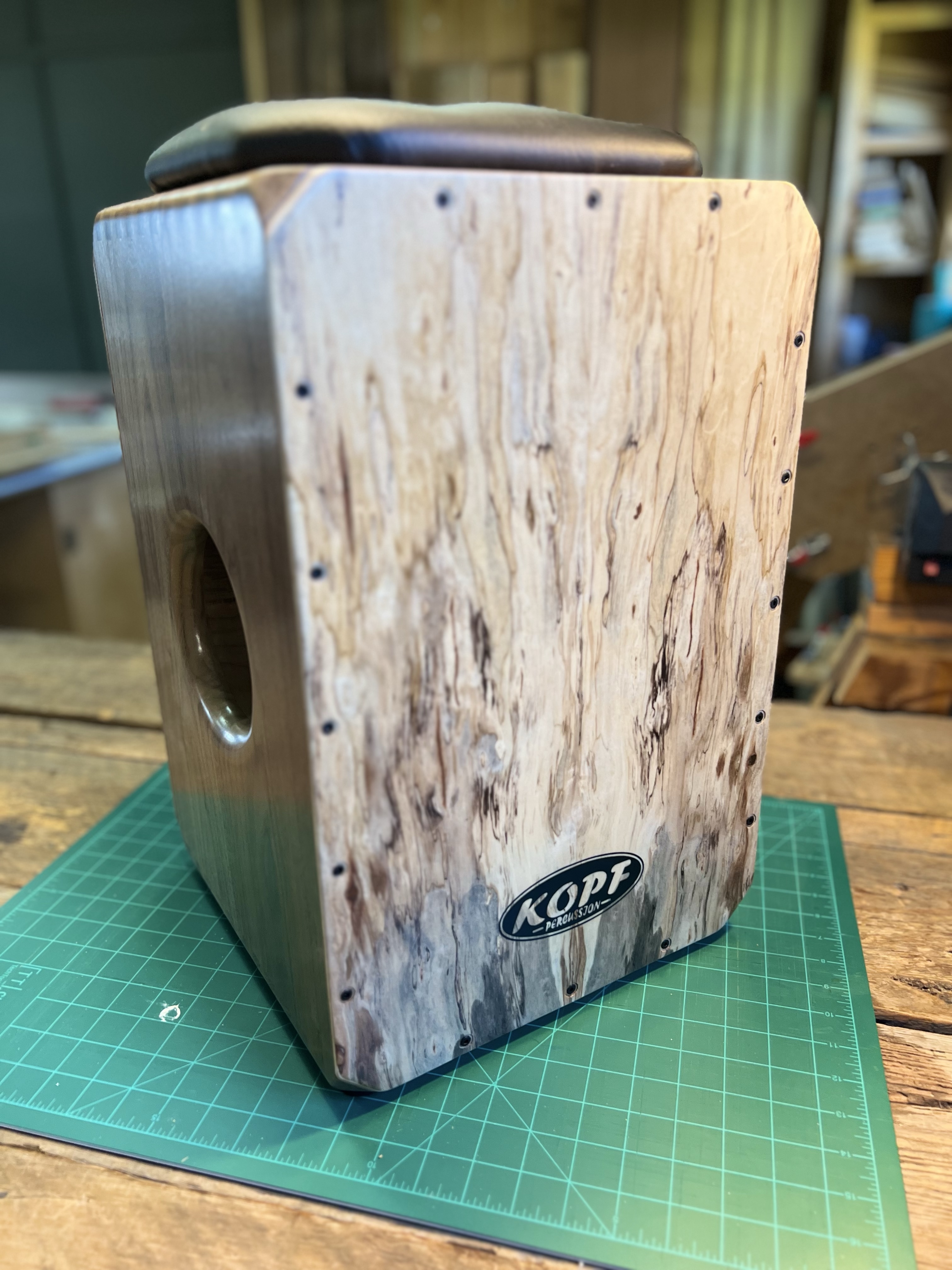

From the very beginning, I knew the body would be walnut. Walnut has always been one of my favorite tonewoods for cajon bodies. It offers warmth and depth, but also a certain richness that fills a room without overpowering. For the faceplates, I needed something with hardness and clarity. Maple is always a strong candidate for that role....it balances beautifully with walnut. But for Ryan’s drum, plain maple wasn’t going to be enough. I wanted something with character. Something alive. That’s when I remembered our conversation about spalting. It clicked immediately. If there was ever a build that called for spalted maple, it was this one. It would tie the story together....our conversation, his influence, and my own love of figured woods. I reached out to suppliers, looking for the right veneer. Not just any spalted maple would do. I needed sheets that were bookmatchable, with clear figure and the kind of spalting that would wake up under finish. It took a while, but after some lengthy searching, I finally found it! It was the perfect veneer for this build.

Innovation: The Integrated Bass Port

There was another detail that made this cajon special. Ryan had asked for a bass port. In the past, I had used plastic insert ports, but they never felt right to me. They got the job done, but they didn’t honor the rest of the build. For a while, I’d been sketching and experimenting with carved, integrated wooden tone ports. It had lived in my head and in a few prototypes, but I hadn’t yet put it into a full build. This was the perfect opportunity to bring that idea to life. So instead of reaching for plastic, I carved a solid walnut bass port that was integrated directly into the body. It was clean, it was strong, and it matched the tone and character of the rest of the instrument. This wasn’t just an aesthetic choice, it was an acoustic one too. The bass response was fuller, more resonant, and felt organic to the drum rather than added on. Why? Because I was able to tune the port to the exact specs of this drum. That's the biggest benefit to making the port myself. It is one of those details that quietly changes everything.

The Build and Emotional High Points

Every cajon I build has moments that stand out, but this one had two that I’ll never forget. The first was when I laid down the initial coat of sealer on the spalted maple faceplates. The grain came alive instantly. The colors deepened, the spalting revealed it's character, and I knew right then this build was going to be special. The second moment was after the assembly, when I gave the drum its first tap. The walnut body resonated, the new bass port moved air like I’d hoped, and the snares cracked with articulation and life. It was the kind of sound that makes you stop and smile. I knew I had hit a home run. Every detail of this cajon was built with precision. From the box-joint joinery to the screw spacing, nothing was left to chance. It’s a discipline I’ve carried into every project: if something can be done precisely, then it should be.

Ryan’s Words

When the cajon was finished, I shipped it off, proud of what I had created but also anxious in that way every builder feels when sending out a special piece. Then Ryan shared his reaction. He didn’t just play it, he gave it a voice. And he wrote words that meant more to me than I can fully express:

“I am absolutely blown away! For my 50th Bday, my lovely and sweet wife Annie Wendel commissioned this gorgeous cajon from Kopf Percussion. The body is black walnut and the two faceplates are made in house from bookmatched spalted maple wood. The visual beauty of this instrument is completely matched by the incredible sound. Even the bass port is made of the same walnut as the body. The joinery is impeccable and the attention to detail that Steve demonstrates is second to none. I'm truly blessed to add this beautiful cajon to my collection and I can't recommend his work more highly! If you're interested in cajons check out Kopf Percussion!”

Those words meant everything to me. They come from someone I have admired for years....someone whose work has shaped my own path. Hearing him describe my attention to detail as “second to none” was humbling and deeply affirming.

More Than Just a Drum

At the end of the day, this cajon is a collection of materials: walnut, spalted maple, snares, glue, screws, and finish. But it’s also more than that. It’s a representation of respect between craftsmen. It’s a reminder that craftsmanship isn’t only about materials and techniques, it’s about intention, discipline, and the relationships created along the way. Every cajon has a story, this one carries both the sound of the cajon and a respect between two makers.

Closing Thoughts

Craftsmanship requires not only patience but humility. It’s about admiring those who came before you, learning from their work, and then striving to build something they would respect in return. For me, this Manito cajon represents both the journey of the build and the connection between two builders. It was an honor to be given the reponsiblility to create it, and an even greater honor to see it come alive in Ryan’s hands. I share this story not just to highlight a build, but to celebrate what it means to be part of a community of makers.... each of us pushing, learning, and respecting the craft we love.

If this story inspires you and you’d like to learn more about commissioning your own build, visit my Custom Cajon page.