Posted by Stephen Head on 15th Jun 2025

What Sound Really Is: And Why I Had to Understand It to Build Better Drums

When I first started building drums, I knew what I liked to hear—tight low-end, crisp articulation, and a clear, focused tone. But I realized that personal preference wasn’t enough. If I wanted to build consistently great instruments, I had to understand what sound actually is—not just subjectively, but physically.

Sound is vibration. That’s the starting point. When something moves—like a tapa, a snare, or even air—it disturbs the air molecules around it. Those disturbances travel outward in waves. When those waves reach your ears, your brain interprets them as sound. It’s not magic. It’s motion.

But as simple as that concept is, what happens between the moment vibration begins and the moment it reaches your ear is surprisingly complex. And that’s where building comes in.

Every decision in drum construction affects how those vibrations behave. The size and shape of the box determine which frequencies get reinforced. The density, stiffness, and grain structure of the wood dictate how efficiently energy is transferred. Even something as small as screw placement or edge sharpness can change how sound waves reflect inside the instrument.

Once I began to understand this, I stopped focusing on vague goals like “add more bass” or “make it pop more” and started asking specific questions about the physics: What frequencies does this shell amplify? How does internal air pressure behave inside this chamber shape and size? Are any standing waves forming that will interfere with tone clarity?

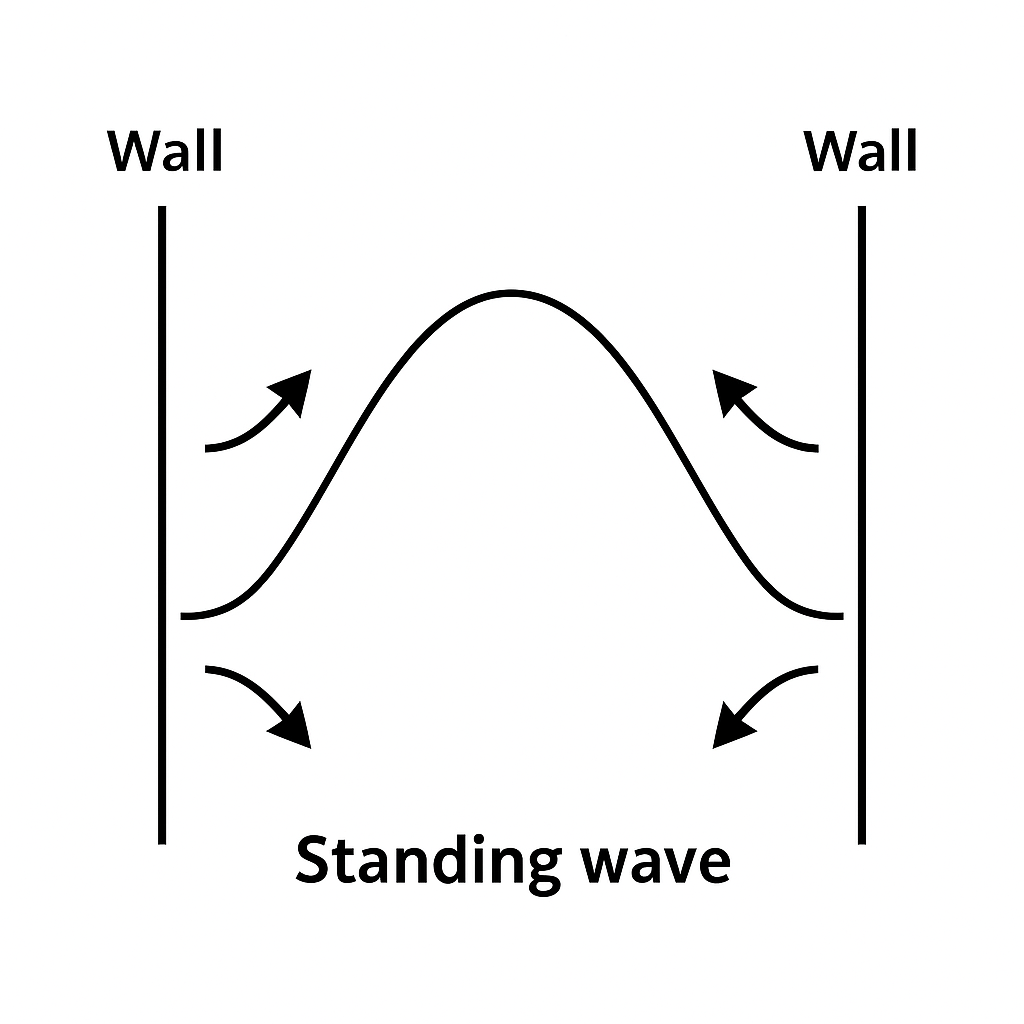

(If you’ve never heard of a standing wave—here’s the idea: when sound waves bounce around inside a drum and the reflected waves align perfectly with the incoming ones, they can reinforce each other. This creates a “standing wave”—a resonant frequency that doesn’t dissipate but instead builds up and dominates. The result is often a single booming note that overpowers the rest of the frequency range. It can make a drum sound boxy, uneven, or muddy. This is the theory behind my dual playing surface design and side soundhole placement.)

You don’t solve that with gimmicks. You solve it by understanding how to manage air volume, surface angles, material damping, and how energy moves through the structure.

Take the tapa. It’s not “tuned” like a drum head—it’s under tension, yes, but not in the traditional definition, its tonal behavior is shaped entirely by its surface area, thickness, species of wood, and ply makeup. That’s it. If it’s too thick or too rigid, it won’t vibrate efficiently. Too thin, and it lacks control. There’s a balance, and it’s based in physics—not guesswork.

Same goes for the shell. I choose wood based on how it transfers vibration—not just how it looks. Walnut, maple, sapele—they each behave differently. Their density and stiffness affect how the box responds to energy, how quickly it rings, and how cleanly it decays.

I also avoid overbuilding. I don’t add excessive bracing or complicated internals. A drum doesn’t need to be overdesigned—it needs to be acoustically clean. I don’t add electronics to fix weak response. I build for natural performance from the start.

The more I’ve studied sound, the more I’ve realized that simplicity, done with precision, always outperforms complexity done without understanding. You can’t hide from physics. Because physics is nature. And when it comes to nature.......you can only work with it—or against it.

So that’s what I do now. I don’t chase trends. I chase acoustic clarity. I build each instrument with purpose, based on how sound actually works.

If you're curious how this same philosophy shapes my broader approach to building, I wrote more about that in What I Do Isn’t Mass Production—And That’s the Point.